Automatic tube thread rolling machine

$4000-30000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Ningbo |

Model No.: ZC28-12.5

Brand: Taohua

Place Of Origin: China

Status: New

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 3 Years

Core Components: Bearing, Pump, Motor, Gear, Gearbox

Warranty Period: 3 Years

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Core Selling Point: Easy To Operate

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Manufacturing Plant, Construction Works, Other

Maximum Rolling Force: 300KN

Rolling Material Diameter: 30-120mm

Roller outer Diameter: 120-210mm

Active force: 15kw

Roller Inner Diameter: 75mm and54mm

Hydraulic Power: 7.5kw

Maximum Roller Thickness: 120mm

Cooling Power: 125w

Spindle Inclination Angle: ±8°

Active Spindle Feed Rate: 20mm/s

1.Introduction for Thread Rolling Machine:

Thread rolling machine is mainly used for rolling various types of precision external thread, high-strength standard parts and anchor bolts and T-shaped screws and other workpieces with larger screw pitch

2.Application for Thread rolling machine:

Automatic Thread Rolling Machine is mainly used for radial cold roll forming, cold rolling process is an advanced non-chip processing technology, the process uses rolling tool extrusion, rolling metal fibers are continuous, rolling generated when pressure should be able to effectively improve the surface roughness, hardness and strength of the workpiece, improve work efficiency than cutting times, even a few times, it can save the material easier to automate processing.Rebar thread rolling machine

Screw thread rolling machine Rolling dies as rolling tool, special strong, suitable for rolling of the workpiece material is not higher than the hardness of HRC37, preferably HRC25 or less, the elongation should be greater than 10%, the tensile strength should be less than 100Kgf/mm (square) various carbon steel, alloy steel and non-ferrous metals, with the improvement of the material hardness of the rolling tool life dramatically

3.Technical parameters for Thread rolling machine:

Maximum Rolling Force: 300KN

Wall thickness of the Processing: not less than 2 mm

Rolling Material Diameter: 30-120mm

No Thread Length Limits: No Limits(Additional Protection)

Roller outer Diameter: 120-210mm

Active force: 15kw

Roller inner Diameter: 75mm and54mm

Hydraulic Power: 7.5kw

Maximum Roller Thickness: 120mm

Cooling Power: 125w

Spindle Inclination Angle: ±8°

Active Spindle Feed Rate: 20mm/s

Weight: 4200±50kg

Machine packing size: 2300x1900mmx2300mm

Cabinet packing size: 900x600x1400mm

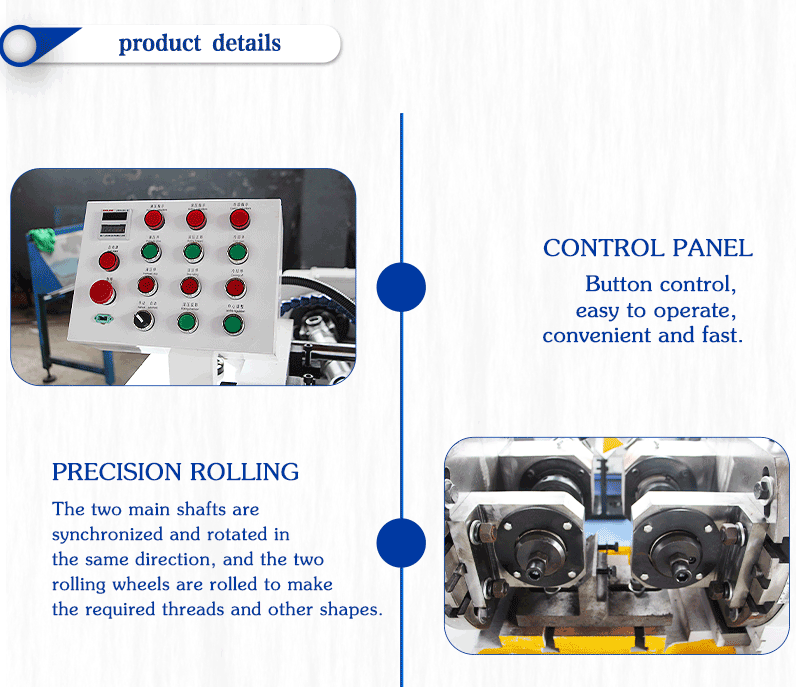

4.More details for Thread rolling machine:

5.Thread rolling machine Workpiece display:

6.Customer visiting for Thread rolling machine:

7.Packing and shipping for Thread rolling machine:

8.Our Clients:

9.Our Exhibition:

10.Why choosing us:

1. We are MANUFACTURER, so we canoffer better price and after-sale service and shorter delivery date.

2.We have strong design & technical capacity,we can design and manufacture as per the customer's requirement.

3. Our factory has been approved CE certificate and ISO certificates etc

4. We have successfully exported to Europe,USA,Middle East, Southeast Asia and so on foreign countries. We all get good feedback.

5.Our product includes Welding Manipulator, Welding Rotator , Welding Positioner ,H beam welding lines,Space Frame Welding Machine,laser welding machine,laser cutting machinelaser cleaning machine,Cnc Flame Plasma Cutting Machine,Edge Milling Machine,Face Milling Machine,magneticpolishing machine,Sheet Metal Deburring Machine,thread rolling machine,bending machine,punching machine etc

6.We provide a FREE TWO YEAR WARRANTY for all our items.

7.OEM brand.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.